Maintenance,Analytical, Nuclear, Force, Dimensional, Temperature, Thermal, Vibration, Sound, Acoustics, Weights, Mass, Instrumentation, Mechanical, Electrical, Pressure Calibrations, Measurements, Reliable, Accurate, Metrologist, Turnaround time, Equipment, Instrument

Calibration

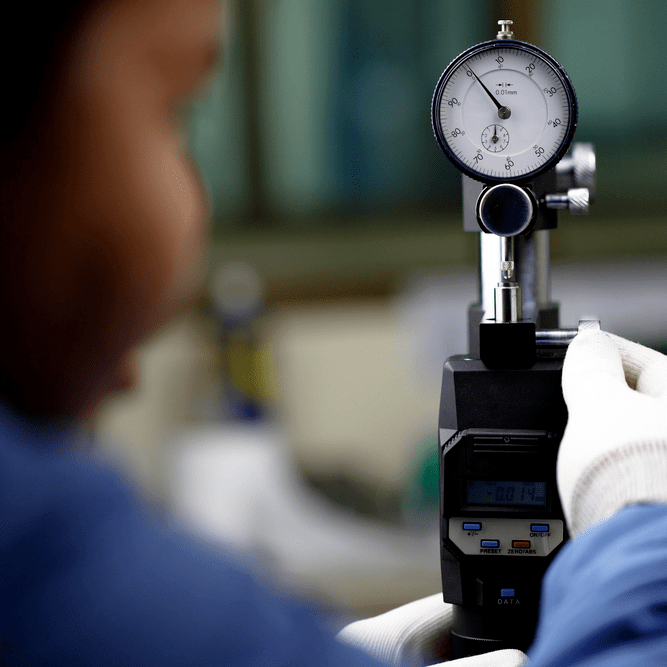

RICI Calibration laboratories are ISO 17025:2017-accredited and equipped with the latest range of instruments operated by experienced metrologists aided by reporting from the Laboratory Information Management System (LIMS).

RICI’s objective is to provide our customers demonstrably reliable instruments for higher accuracy and precision. Our extensively-trained metrologists use the most up-to date standards to calibrate equipment.

RICI’s expertise in metrological measurements allows the company to offer services in the following measurement areas:

1. Electrical

2. Mass & Weights

3. Acoustics

4. Vibrations

5. Force

6. Pressure

7. Dimensional

8. NDT Equipment

9. Nuclear

10. Thermal

11. Mechanical

12. Civil Equipment

13. Chemical & Analytical Equipment

The diverse range of RICI’s capabilities allows us to carry out calibrations for most industry equipment, including on-site calibrations.

Your accuracy is our business!

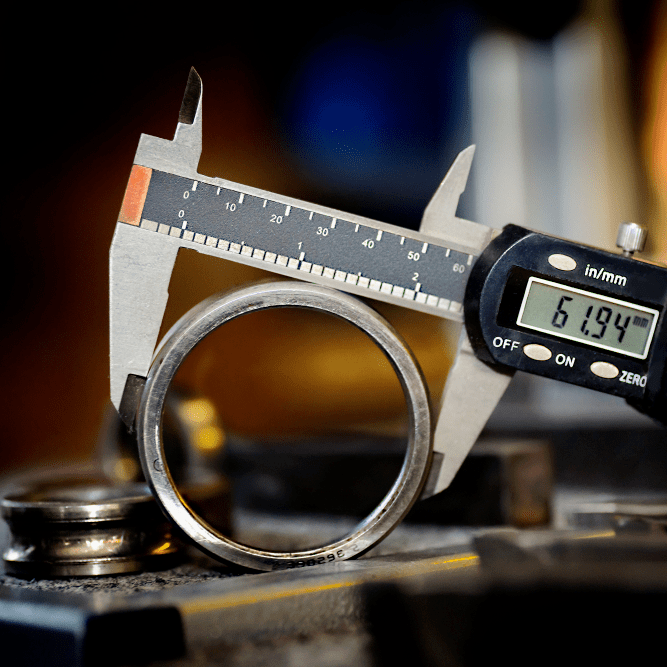

Dimensional

RICI’s ISO 17025 accredited calibration services were designed to ensure that your hand tools and measuring instruments provide reliable, precise, traceable measurement results. From length measurement calibration of instruments such as micrometers, calipers, gages or tape measures, to high-tech optics-based scales and comparators, our industry leading dimensional instrument calibration capabilities are designed to reduce risk and inaccuracy in your measurements. Our dimensional capabilities also

include surface hardness and roughness tester calibration for select instruments. Geometric Dimensional & Tolerance (GD&T) such as custom overlays and gaging, and we provide custom dimensional analysis for first article, annual inspection, and capability study part inspection requirements. RICI offers Dimensional Calibration Services in many of our accredited calibration labs across Saudi Arabia and Bahrain. Additionally, our laboratories include reference level capabilities for dimensional standards including end measuring rods, gage blocks, ring gages, and master setting plugs. For the most stringent commitment to measurement and uncertainty control, you can trust that the quality and metrology experts at RICI to deliver industry-leading dimensional tool calibration services. RICI has a climate-controlled laboratory to stabilize instruments and our team of dimensional calibration technicians are highly experienced. We provide customers in varied industries with gauge, micrometer, caliper and other tool calibration services, and also calibrate masters and length standards. The technicians work in a state-of-the-art, temperature and humidity controlled laboratory for the most accurate measurement. The room is maintained at 20°C with 30-50% relative humidity. After calibration is complete, you will receive a detailed Certificate of Calibration. Information about measurement traceability, accreditation and the instrument’s condition, including any out-of-tolerance conditions and adjustments made during calibration, will be clearly reported on the certificate. Dimensional calibration is performed by comparing the performance output of a hand tool, gauge or another measuring instrument with a measurement standard to confirm that the item produces results which meet or exceed that standard’s criteria. “As found” and “as left” descriptions of the instrument’s condition, our accreditation and details about any adjustments or repairs are reported in a Certificate of Calibration.

Our capabilities include:

- 1-2-3 Blocks

- Angle Blocks

- Balances

- Bench Micrometers

- Bore Gauges

- Cables

- Caliper Checkers

- Calipers/Verniers

- Crimpers

- Depth Micrometers

- Dial Indicator (C)

- Dimensional Tapes

- Durometers

- Wire Gauges

- Electronic Gauges

- End Rods/L/S

- Feeler Gauges

- Gram Gauges

- Height Gauges

- Hardness Testers

- Angle Plate

- Levels

- Micrometers

- Microscopes

- Parallels

- Profilometers

- Gauge Blocks to 20 in.

- Viscometers

- Protractors

- Pull Testers

- Ring Gauges

- Riser Blocks

- Rules

- Scales

- Glass Scales

- Screw Pitch Gauges

- Pin Gauges

- Plain Plug Gauges

- Torque (D/W)

- Torque Presets

- Torque Standards

- V Blocks

- Sine Bars

- Sine Plates

- Squares

- Surface Testers

- Surface Plates

- Tape Measures

- Telescoping Gauges

- Thickness Gauges

- Thread Plugs

- Thread Ring Gauges

- Toolmaker’s(M)

- Weights

- Wires (Thread)

multimeter calibration services, dimensional calibration, laboratory calibration services, test gauge calibration, nstrumentation and calibration, testing and calibration, mechanical calibration services, oven calibration, iso 17025 accredited calibration labs, industrial calibration

Thermodynamics

RICI has developed temperature mapping procedures and calibration reports to adhere to ISO/IEC 17025 requirements. Implementation of the Calibration Services Technical Manual and Equipment Calibration Services Quality Manual ensures our continuing adherence to these international standards. With the direct comparison method, we are capable of producing highly accurate and consistent results across the entirety of our temperature calibration scope. Temperature measurement plays a crucial role in almost every industrial sector.

Calibration of the temperature measuring instruments used, e.g. data loggers, thermal imagers, immersion/penetration probes, thermocouples, etc., is therefore vital. At RICI, you can choose the right calibration points for your measuring instrument according to your individual quality requirements. We calibrate in a range from -196 to +1200 °C with the smallest measurement uncertainties.

Scope of calibration

- Visual inspection and cleaning

- Technical inspection of equipment functions

- Calibration certificate with target/actual values and measurement uncertainties

- Calibration identification with calibration labelling

- Repair, replacement and adjustment in consultation

Surface Temperature

In addition to the classic temperature measuring instruments, companies also use measuring devices to check the surface temperature. As an accredited calibration laboratory, RICI has the expertise for contact or non-contact calibration of surface temperature probes and sensors. In the field of contact surface measurement, we calibrate cross-band probes, mushroom cap sensors or other sensors with special designs. The unique factor is the accredited calibration according to DIN EN ISO/IEC 17025:2018. Non-contact surface temperature measurements are made during the calibration, for example, of thermal imagers and pyrometers. For this we have several black bodies and are accredited in the range from -18 °C to 350 °C.

Humidity

The precise calibration of humidity measuring instruments requires superior metrological expertise. RICI’s accredited humidity laboratory is one of the best in Europe with a measuring uncertainty of up to 0.2% RH in a measuring range from 5 to 95% RH (-18 to +90 °C). The calibrations are performed in different climatic chambers such as the Thunder or Huminator or in a humidity generator specially designed together with the PTB.

Our capabilities include:

- Autoclaves

- Freezers

- Infrared Thermometers

- RTDs

- Furnace calibrations

- Temperature Controllers

- Incubators

- Temperature Humidity D/L

- Humidity Meters

- Incubators

- Ovens

- PRTs

- Hygrothermographs

- Environmental Chambers

- Hygrometers

- Thermocouples

- Temperature/RH Chart Recorders

- Thermometers

- Environmental Chambers

- Temperature Mapping/Profile

- Refrigerators

- Temperature Dry Wells

- Temperature Baths

- Temperature/RH Meters

- Temperature Blocks

Electromagnetic

Our trained calibration technicians provide professional calibration for all types of electronic measuring instruments. Our electronic laboratory is fully equipped to calibrate electrical/electronic instruments for DC and AC voltage, current, resistance, time and frequency.

Our capabilities include:

- Accelerometers

- Resistors

- Ammeters

- Light Meters

- Capacitors

- Logic Analyzers

- Sound Level Meters

- Rectifiers

- Power supplies

- Megohmmeters

- Spectrophometers

- Decade LCR Box

- Multifunction Calibrators

- Digital Multimeters (DMM)

- Mulitimeters

- Static Meters

- Inductors

- Ionizers

- Conductivity Meters

- Variable Auto Transformers

- Stopwatch & Timers

- Gaussmeters

- Panel Meters

- Tachometers

- pH Meters

- Resistivity Meters

- Oscilloscopes

Mechanical

Our mechanical calibration services cover a number of metrology disciplines including: Length, Force, Mass, Torque, Vibration, Pressure and Viscosity. The laboratory is housed within a temperature controlled environment to maintain thermal stability of both the reference standards and instruments under test.

We realize the performance and accuracy of your mechanical, dimensional and physical test equipment is critical to your organization success so we use high quality, reliable reference standards for our calibration tasks. We pride ourselves on providing professional mechanical calibration services to ensure your measurement instruments are accurate, reliable and traceable. Due to the frequent handling, mechanical shock and exposure to various atmospheric conditions, it is inevitable that mechanical instruments will be subject to drift. To understand this drift during its’ operational service, a regular calibration schedule is required to determine the measurement shift between subsequent calibrations and to determine tolerance limits for the measurement uncertainty budget. Force Gauge Calibration in tension and compression up to 50 kN for the calibration of load cells, force gauges and push/pull gauges. Torque Wrench Calibration covering 1 to 1000 Nm for the calibration of torque wrenches and torque screwdrivers. Calibration can be undertaken to a selection of standards upon request. Balance and Scale Calibration from 1 mg to 500 kg for the calibration of laboratory balances, benchtop balances, benchtop scales, floor scales, aircraft scales, hanging scales, personal weigh scales and load cell platforms. All our mechanical, dimensional and physical calibrations are conducted under the guidelines of ISO/IEC 17025 throughout the laboratory process, including certificate reporting, measurements and traceability. A range of onsite calibration services are available for the support of automotive and aviation repair workshops. If you require, your calibrations can be added to our recall database for email reminders 30, 60 and 90 days prior to calibration due date.

Our capabilities include:

- Pressure Gauges

- Pressure Transducers

- Compound Gauges

- Pressure Indicators

- Load Cells

- Microscope

- Stop Watch

- Total Stations

- Tachometer

- Charpy Impact Testing Machines

- Compressors

- Level Transmitters

- Anemometers

- Pressure Transmitters

- Pressure Valves

- Pressure Controllers

- Dead Weight Testers

- Direct Shear Apparatus

- Force Indicators

- Force Gauges

- Force Transducers

- Force Sensors

- Dumpy Level

- Automatic Levels

- Vicker Hardness Testers

- Brinell Hardness Testers

- Rockwell Hardness Testers

- Lux Meter

- Magnetometer

Analytical and Maintenance

RICI demonstrates competence, measurement capability, and traceability in our calibration service. Calibration certificates issued by RICI contain the measurement results, including the measurement uncertainty and/or a statement of compliance with an identified metrological specification. RICI laboratories are accredited to ISO 17025. Our accreditation documentation is maintained by the Quality Manager (QM).

RICI’s calibration lab prides itself on being able to provide our customers with demonstrably reliable services of Analytical Calibrations & Maintenance in the following areas; Calibration Services in Bahrain and Saudi Arabia.

- Chromatography and Separation Analysis Equipment HPLC, UPLC, GC, GCMS, LC/MS etc.

- Compound Structures Analysis Equipment FT-IR, UV-VIS Spectrophotometer, XRD, NMR, NIR etc.

- Elemental Analysis Equipment ICP, ICP-MS, IC, TN Analyzer, NC Analyzer, XRF etc.

- Surface Analysis Equipment Microscope, Spectrometer, TDS etc.

- Thermal Analysis Equipment TG, DTA, DSC etc.

- Laboratory Equipment Flash Point Testers, Calorimeters, TOC Analyzers,

- Dew Point Analyzers, PH Meters, Conductivity Meters, Viscometers, Pour Point Testers etc.

- Chromatography and Separation Analysis Equipment HPLC, UPLC, GC, GCMS, LC/MS etc.

- Compound Structures Analysis Equipment FT-IR, UV-VIS Spectrophotometer, XRD, NMR, NIR etc.

- Elemental Analysis Equipment ICP, ICP-MS, IC, TN Analyzer, NC Analyzer, XRF etc.

- Surface Analysis Equipment Microscope, Spectrometer, TDS etc.

- Thermal Analysis Equipment TG, DTA, DSC etc.

- Laboratory Equipment Flash Point Testers, Calorimeters, TOC Analyzers

- Dew Point Analyzers, PH Meters, Conductivity Meters, Viscometers, Pour Point Testers etc.

We tackle every variable of our measurement process to ensure the reliability of calibration, which leads to accurate results in your procedures, products and services. We are proud of our unaltered quality standards and reputation for excellence. Furthermore, all of our calibration services are backed by a team of trained metrology experts, unique purpose-built facilities, experienced calibration specialists and a skilled customer service team whose sole goal is to deliver the most consistent and trustworthy calibrations available. Therefore, the accuracy of all the equipment involved in quality and safety control must be monitored. If the equipment is malfunctioning, it can translate a wrong impact on the reading. For example, if a thermometer used to check a critical heating temperature is not reading accurately, it won’t show up unless the thermometer is verified and calibrated. Hence, RICI ensures that the equipment readings are accurate and give control of the process.

RICI is offering different types of maintenance services as mentioned below:

On-Call Services

- Field Resident Engineers

- Fault Diagnosis of Equipment

- Preventive Maintenance Services

- Breakdown Maintenance services

Furthermore, our maintenance program ensures that the equipment performs unfailingly, functions as anticipated and meets process requirements. A preventive maintenance program is based on the equipment manufacturer’s guidelines or on the conditions and period of operations. As a result, they should be managed to ensure that all equipment is in top condition and can produce safe products.

So, START NOW! – Need a quote for calibration services or just want to do a “temperature” check? We are just a phone click away.