Our Services

-

Calibration

We offer precise and reliable calibration services to ensure your equipment meets industry standards, enhancing accuracy and operational efficiencyLearn more -

Inspection

Comprehensive inspection services ensure quality, safety, and compliance, supporting industry standards and fostering operational trust.Learn more -

Testing

We offer testing services to ensure your equipment meets top quality and safety standards, boosting performance and compliance.Learn more -

Certification

Certification services validate compliance with industry standards, enhancing credibility and fostering trust in your operations.Learn more -

Training

Professional training programs build expertise and empower teams, driving competency and continuous improvement in your organization.Learn more -

Health & Safety

Our Health & Safety services help ensure a secure workplace by assessing risks and implementing safety measures to protect your team and operations.Learn more

Featured Insights

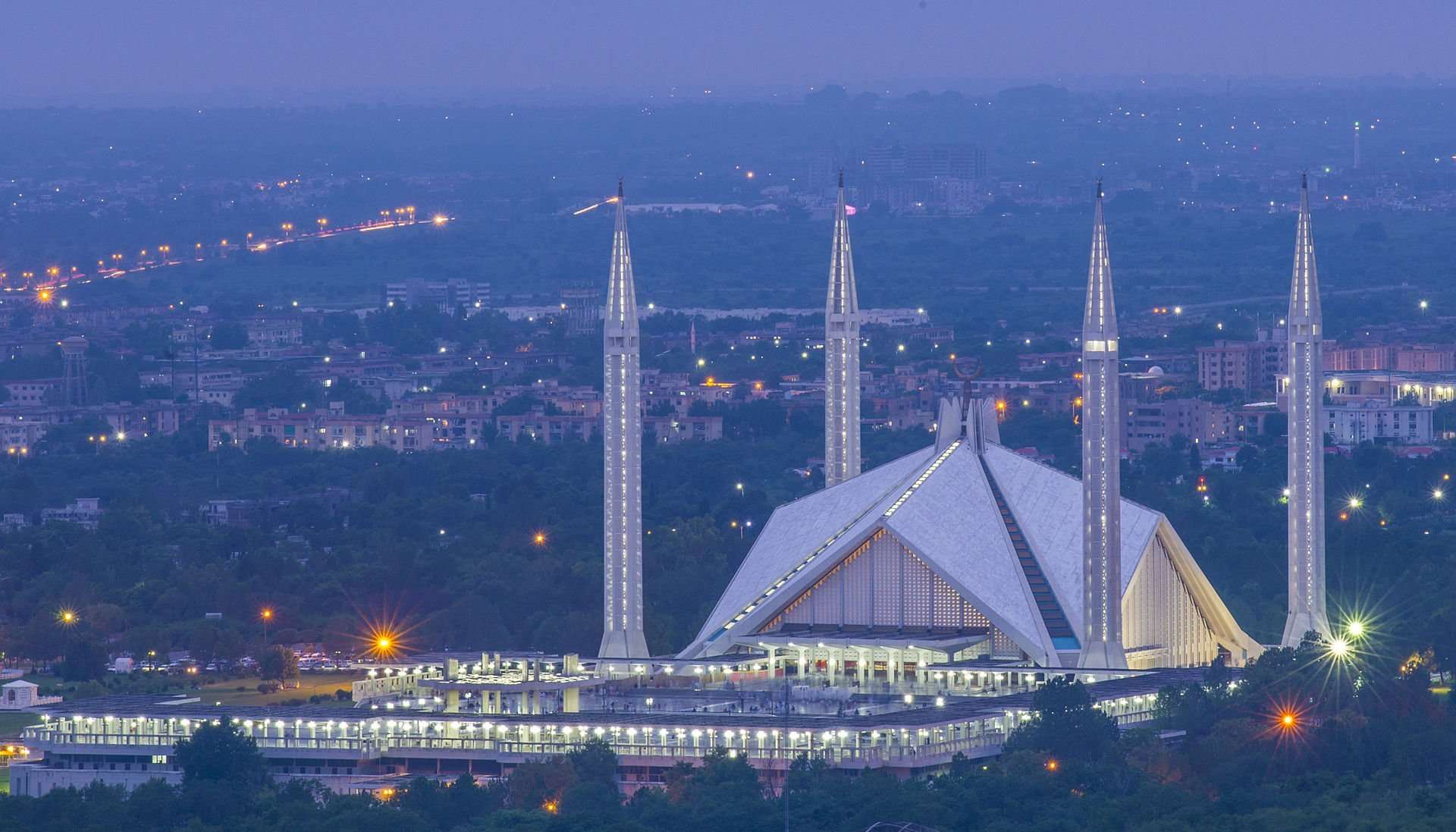

Translating technology into a positive impact

Our approach allows us to deliver exceptional experiences that drive growth and success for all stakeholders. Let’s rise to new heights with the power of digital transformation.

6,500

Certified Companies

9,300

No. of Trainees

9

World Wide Branches

35

World Wide Partners